- Fans/Air Ventilator

- General Centrifugal Fan

- ZHT-35 Axial Fan

- Fire-fighting Smoke Exhaust Fan

- Turbine Ventilator

- Textile Axial Ventilator

- BDW-L Roof Centrifugal Fan

- BDW-87-4 Roof Centrifugal Ventilator

- WBTD Type Roof Ventilator

- SXG Type Inclined Flow Ducting Ventilator

- SWF Type Mixed Flow Ventilator

- GLF Air Blower Case

- Direct Drive Wall Mount Exhaust Fan

- Double Inlet Centrifugal Ventilator

- High Pressure Centrifugal Ventilator

- Inline Centrifugal Ventilator

- Induced Draft Fan

- High pressure centrifugal blower

- Cooling Towers

- DFN Cooling Tower

- DBNL3 Normal Type Cooling Tower

- Ultra Low Noise Cooling Tower

- DFB Close Type Cooling Tower

- DFH Square Shape Cross Flow Cooling Tower

- GFNL Series Steel Frame Square Shape Counter Flow Cooling Tower

- Industrial Cooling Tower of Reinforced Concrete Frame

- Water Tank

- SMC Combined Water Tank

- Assembled Hot Dipped Galvanized Steel Water Tank

- Stainless Steel Water Tank

- Stainless steel round water tank

- FRP Laboratory Facility

- Fume Hood

- Lab Bench

- Reagent Shelf

- Medical Cupboard

- Balance Table

- Ventilation Accessories

- Air Vent

- Fire Resisting Damper

- Muffler

- Water Chiller

- Air Cooled(Heating) Chiller Unit

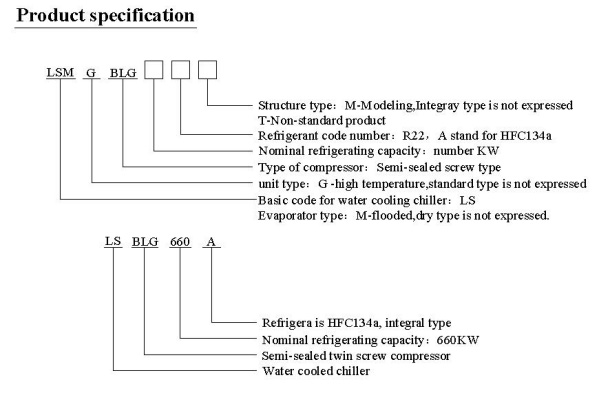

- Water Cooled Chiller

- LM Full Liquid Type Water Cooled Chiller Series

- Ground Source Heat Pump Unit

- Full-liquid Type Ground Source Heat Pump Unit

- Variable Frequency Water Household Central Air Conditioning

Please Contact Us!

العربية

العربية Português

Português Français

Français Español

Español English

English